|

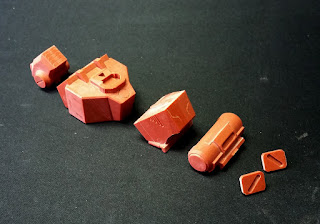

| 2 part machined |

A little disappointed I the cylinder has facets it wasn't obvious in the 3D model I guess because its such a big cyclider (3cm dia) even with 100sides it shows 'flats'. Any who I'll give it a quick buff with 400 paper to smooth it down.

Next the task of working out the gun and torso joint. And I can tell you it was a tricky mess to sort out it took 3 days of reworking to finally get something that could be swapped as a single gun yet still retain strength in both the guns bridge and the shoulder joint in the torso all of which wanted the same space.

|

| Open chest surgery |

As you can see a huge bite is taken out of the torso for the gun and how the shoulder joint prevents any simple solutions.

And here with have the Support structure clean cut along the AC20 line with any under cuts removed and added to the gun its self to allow the gun to slip over the torso. (those holes are locations for magnets)

And how the AC20/torso are divided

On to machining the torso is taking 30hrs to rough front of the torso alone! yikess so I decided to start that while I write the rest of the code for finishing

Making sections in such big parts is tricky (and stressful for me) the challenges of over looking something go up 10 fold as your at the maximum dimensions the mill and milling bit can do leaving bingo margin for error.