This'll be a long post td:lr

"leopards gone to the printers, TT scale dragon and cent arrived."

My printer services uses swept volume to price prints, it means you pay for the an imaginary box that your model would fit in. Pricing in 3D priniting is cubed so every mm oversize you playing a hefty multipul for it. But the up side is you can stuff a lot of things in to the void space around and inside larger parts.

The first quote I received was enough to floor me enough to buy a small second hand car. But it was a rough cobble together just to get an idea of cost I knew there a lot i could do to get the swept volume down.

And so began a 2day game of 3D Dropship Tetris. I managed to get a swept volume decrease of 50% yippee!

what you see below is the final result

"resistance is futile"

That brought the print into an acceptable price range along with the following adjustments;

- I had to scale the drop ship down to 6.1cm door height (the ceiling I thinned to allow 6.4cm ceiling height) so the altas

may have to stoop to get in but that small decrease in high brings in good cost reduction.

- I added a pop-out panel to the dropship nose (top left) to be able to utilise the interior space. I managed to get in one of the thrusters (netting a big cost saving) and a few other odd items. The void space in the nose will be filled and the pop out panel added back for casting.

- I still had some voids left over and decided to fill this with dropship bric-a-brac. I made shipping containers (six), crates (six) and ammo boxes (eighteen). I made them stackable too. You can see them nested in the top right picture. If I have any left over RTV I'll make some casts of those but that's a stretch goal otherwise They'll be for decoration for my personal model.

- I knew all along I would have to go for SLS printing on this. Since it would be larger than the mechs I've printed and cost would be high. SLS is common form of printing and one of the cheapest profession grade prints. However the surface (pitted/printlines) needs a prep and details can easily vanish in the printing process. With that in mind all the details I added are chunky and scaled appropriately for what the printer should be able to do. I have some special filler paint and i plan to spend a good deal of time surface prep'ing the model so that it should be good to paint right out the mould.

So the order has been placed etc is 10working days.

And something that came from UPS today;

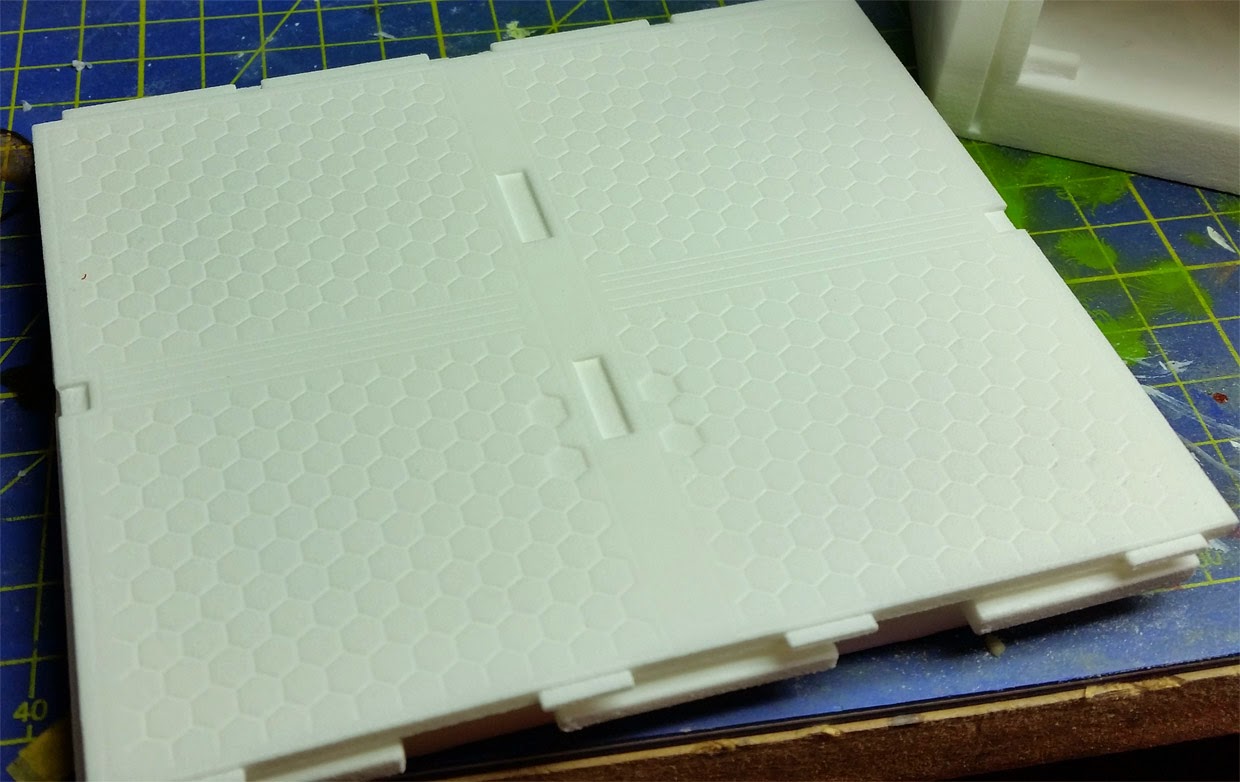

Fresh out the bag. Table top scale dragon and centurion. I'll pop them into the sonic cleaner with some degreaser to get the free off the printing wax. If your wondering the cent looks a little taller but that's just because I didn't fuse his parts before printing so he's a bit stretched. I'll glue him before casting (tosro, left arm, left leg, right arm, right leg) The details aren't going to be super sharp at this scale but they're on par with the metal Battech minis. Just some fun to go with the dropship and scales of the bigger 1/60 stuff.

And finally

We expecting another addition to the family before the end of the month (the wife's thinking next few days). So once that does happen it tend to be chaos for at least 6 weeks which dumps us right at the 4weeks of Christmas chaos so more updates might be sparse.